Views: 0 Author: Site Editor Publish Time: 2025-06-23 Origin: Site

Router bits are essential components in woodworking, construction, and DIY projects. These versatile tools allow woodworkers and carpenters to shape, cut, and finish wood with precision and creativity. From creating straight grooves to detailed mortising, router bits come in a variety of shapes and sizes, each designed for specific tasks. Understanding the different types of router bits and their applications is crucial for anyone working with wood, whether in professional construction sites, woodworking shops, or home projects.

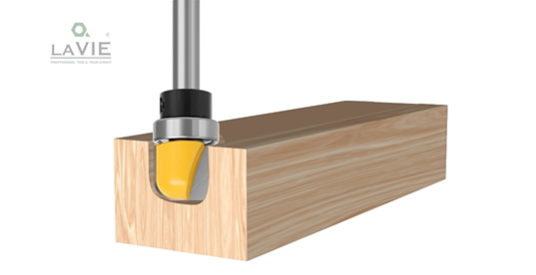

Router bits are cutting tools attached to routers, powerful handheld or table-mounted machines that spin the bits at high speeds. These bits remove wood to create precise shapes, edges, and joints. The quality and type of router bit significantly affect the accuracy and finish of woodworking tasks. For professionals and hobbyists, selecting the right router bit can mean the difference between a rough cut and a smooth, professional-grade finish.

Router bits are typically made from high-speed steel (HSS) or carbide-tipped materials, ensuring durability and sharpness. Carbide bits tend to last longer and offer cleaner cuts, especially in hardwoods and dense materials.

Straight bits are among the most commonly used router bits. Their simple cylindrical shape with straight cutting edges makes them ideal for cutting straight grooves, dados, and slots in wood. These bits are perfect for joinery, such as creating mortises for tenons or grooves for cabinet panels.

Cutting wood slots and grooves for shelving or panel inserts.

Trimming edges and making rabbets.

Hollowing out areas in wood for inlays or hardware installation.

Straight bits come in various diameters and cutting lengths, allowing for versatility in depth and width of cuts. Using a straight bit ensures precise, clean slots essential for structural stability and aesthetic quality in wood projects.

Flush trim bits are designed with a bearing on the tip, allowing the bit to follow templates or previously cut edges precisely. This makes them indispensable for trimming laminates, veneers, and workpieces to match patterns.

Trimming wood edges flush to templates or adjoining surfaces.

Finishing laminated edges on cabinets or furniture.

Copying patterns or designs using template routing techniques.

The bearing acts as a guide, preventing the bit from cutting beyond the edge of the template. This ensures exact replication of shapes and smooth edges, which is especially useful for repetitive or complex designs.

Corner round bits are designed to soften sharp edges by cutting a rounded profile. These bits are popular in cabinetry and furniture making to add decorative touches and to increase safety by removing sharp corners.

Rounding edges of tabletops, shelves, and furniture corners.

Creating decorative trim profiles.

Softening edges on doors and cabinetry for a polished look.

Available in different radii, corner round bits allow woodworkers to customize the curvature to suit the project’s style and function. This small detail can significantly enhance the final product’s appearance and usability.

Raised panel bits are specialized bits used to create the distinctive raised center panel commonly seen in cabinet doors and furniture panels. These bits typically have a pilot bearing to guide the cut and produce a smooth, decorative profile.

Crafting raised panels for doors and cabinetry.

Adding ornamental profiles to furniture panels.

Shaping wood panels for architectural millwork.

Because raised panel bits often have complex cutting edges, they require routers capable of handling deeper cuts and careful setup. The result is a professional-grade finish that adds elegance and dimension to woodwork.

Mortising bits are designed for cutting square or rectangular mortises in wood, which are essential for strong joinery when combined with tenons. These bits are used in making furniture, doors, and frames where structural integrity is key.

Cutting mortises for mortise-and-tenon joints.

Creating slots for hinges or locks.

Precision joinery in doors and furniture making.

Unlike straight bits, mortising bits are often paired with specialized mortising routers or machines that allow for exact control of depth and shape. This precision ensures tight, durable joints critical for high-quality woodworking.

Router bits are indispensable tools in various settings, from large construction sites to small home workshops.

Construction Sites: Used for creating precise joints and finishes in framing, cabinetry, and finishing carpentry. Durable bits withstand heavy usage and varied wood types on-site.

Carpenters: Benefit from the variety of bits to perform detailed woodworking, custom cabinetry, and furniture making. The ability to switch bits quickly allows for versatile workflows.

Daily DIY Projects: Hobbyists and home improvement enthusiasts rely on router bits for home repairs, furniture building, and decorative woodworking. User-friendly bits like flush trim and corner round bits help achieve professional results with minimal experience.

Selecting the correct router bit depends on the specific task, material, and desired finish. Factors to consider include:

Material of the bit: Carbide-tipped bits for hardwood and frequent use, HSS for softer woods and occasional projects.

Bit shape and profile: Straight for slots, flush trim for templates, corner round for edges, raised panel for decorative panels, and mortising for joints.

Shank size: Ensure compatibility with your router collet (typically 1/4” or 1/2”).

Investing in quality bits and proper maintenance—such as cleaning and sharpening—can extend the lifespan and performance of your tools.

Proper care of router bits ensures optimal performance and safety:

Clean resin and pitch buildup after use.

Store bits safely to avoid damage.

Sharpen or replace dull bits promptly.

Use proper speed settings on routers to prevent overheating.

Good maintenance practices reduce wear and help maintain the precision required for high-quality woodworking.

Router bits are the foundation of precise and creative woodworking. From straight bits for slotting and trimming to mortising bits for strong joinery, understanding their functions and applications empowers woodworkers to execute a wide range of projects efficiently. Whether you are a professional carpenter, construction worker, or DIY enthusiast, selecting the right router bit and maintaining it properly will enhance your craftsmanship and project quality.

For those interested in sourcing high-quality router bits suitable for diverse woodworking applications, companies like YUEQING LAIWEI TOOLS CO., LTD offer extensive product lines tailored to meet professional and hobbyist needs. Visit their website at www.lavietools.com to explore their offerings and ensure you have the right tools for your next woodworking project.