Views: 0 Author: Site Editor Publish Time: 2025-05-28 Origin: Site

In the woodworking and construction industries, achieving both aesthetic beauty and structural integrity is a challenging but vital goal. The success of a project often depends not only on the choice of wood and design but also heavily on the tools used to shape and join wood pieces. Router bits, particularly advanced types like Raised Panel Bits and Mortising Bits, play a crucial role in this regard.

Router bits have been essential in woodworking for decades, evolving from simple cutting tools to sophisticated precision instruments. While common router bits such as straight and flush trim bits are fundamental for routine shaping and trimming, advanced bits like Raised Panel and Mortising Bits address more complex needs.

In construction and carpentry, the demand for speed, accuracy, and consistency is ever-increasing. These router bits enable craftsmen to achieve intricate designs and strong joints efficiently. For instance, cabinetry and door manufacturing rely heavily on the distinct profiles created by raised panel bits, while mortising bits ensure tight, load-bearing joinery through mortise and tenon connections.

Moreover, with the rise of DIY culture and small-scale custom woodworking, these bits are no longer confined to industrial workshops—they are accessible and valuable to hobbyists who aspire to professional-grade results.

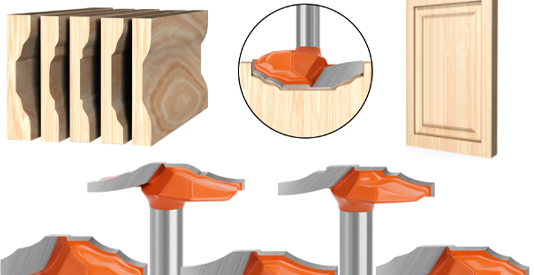

Raised Panel Bits are uniquely engineered to shape wood panels with a raised, contoured profile along the edges. Unlike flat panels, raised panels bring depth and richness to cabinetry, doors, and furniture. These bits usually feature complex cutting edges that produce a bevel combined with a curved profile, resulting in an elegant “raised” effect.

Typically, raised panel bits are larger in diameter—ranging anywhere from 1.5 inches to over 3 inches—and include a pilot bearing. The pilot bearing guides the bit along the panel’s edge or a template, ensuring precision and reducing errors. This design helps maintain smooth curves and consistent patterns even on wide panels.

Raised panels are a staple in both traditional and modern woodworking styles. They provide a timeless look that suits everything from colonial-style kitchen cabinets to sleek contemporary doors. The raised edge not only enhances the panel's aesthetic appeal but also contributes to the panel's structural integrity by stiffening the wood and helping prevent warping or bowing.

In cabinetry, raised panel doors are favored for their elegant and professional appearance. Custom kitchens, bathroom vanities, and built-in storage solutions frequently utilize raised panels to elevate design and value. Additionally, raised panels are common in architectural millwork, where intricate profiles add sophistication to interior spaces.

Construction sites benefit from raised panel bits because they allow carpenters to quickly replicate detailed designs that would otherwise require time-consuming handwork. The ability to choose from various bit profiles—ranging from simple bevels to intricate ogee or classical curves—grants artisans extensive creative control.

Professional Quality Finishes: Raised panel bits provide a crisp, smooth finish that is difficult to achieve with manual tools.

Consistency and Uniformity: These bits produce identical profiles on multiple panels, ensuring a cohesive look across doors and cabinetry.

Efficiency and Productivity: Large diameter bits cut substantial profiles in one or two passes, reducing overall production time.

Versatility: Compatible with hardwoods like oak, maple, and cherry as well as softwoods, these bits are adaptable to various wood types and project requirements.

Mortising Bits are specialized tools used to carve out mortises—precise, rectangular cavities in wood that accept tenons for mortise and tenon joints. This joint has been the gold standard in woodworking for centuries, prized for its exceptional strength and durability.

Typically, mortising bits are straight router bits with robust cutting edges designed to produce clean and accurate mortise cavities. Some systems combine hollow chisels with bits, providing even more precise and square cuts ideal for heavy-duty joinery. This technique is especially popular in timber framing and furniture making.

The mortise and tenon joint joins two wood pieces by fitting a tenon (a projecting tongue) into a mortise cavity, creating a mechanical bond that resists tension, compression, and twisting forces. When properly executed, this joint is stronger and longer-lasting than many mechanical fasteners like screws or nails.

Using a Mortising Bit helps carpenters create consistent mortises that precisely fit the tenons, ensuring tight joints. Precision is crucial because gaps or loose fits can lead to weak connections and structural failures. The bit allows for controlled depth and width, making the mortise suitable for the joint’s specifications.

Door and Window Frames: Mortise and tenon joints hold the frame elements securely, allowing doors and windows to function smoothly without sagging.

Furniture: Chairs, tables, beds, and cabinets rely on mortise and tenon joinery at critical stress points, enhancing stability and durability.

Timber Framing: Large-scale wood structures, such as pergolas and timber-framed houses, utilize mortise and tenon joints for load-bearing connections that last generations.

While Raised Panel Bits contribute significantly to the visual appeal of wood projects, Mortising Bits are fundamental to their structural strength. The two bits complement each other perfectly, enabling woodworkers to create products that marry beauty with durability.

For example, in cabinet door construction, the frame is typically assembled with mortise and tenon joints for maximum strength. The inner panel, often a raised panel, fits snugly within this frame, adding aesthetic value while allowing for natural wood movement.

This synergy means that carpenters can produce high-quality products more efficiently, avoiding the need for metal fasteners or complicated joinery methods that increase costs and labor time. The combination also simplifies repairs and modifications since components fit together cleanly and securely.

Always use bits made of high-quality carbide or steel to maintain sharpness and durability.

Adjust router speeds appropriately: larger diameter bits require slower speeds to prevent burning, while smaller bits can run faster.

Use appropriate guides, fences, and featherboards to control the workpiece and prevent kickback.

Perform multiple shallow passes rather than deep cuts in one go to reduce strain on both the bit and wood.

Ensure proper dust extraction to maintain visibility and prevent clogging.

Always wear safety gear: eye protection, hearing protection, and dust masks are essential.

Raised Panel and Mortising Bits work well with both hardwoods (oak, maple, cherry) and softwoods (pine, fir, cedar).

Hardwoods provide better finish quality but require sharper bits and slower feed rates to avoid chip-out.

Softwoods are easier to work but may tear out if speeds are too high or bits are dull.

Avoid routing wood with knots or defects near cutting paths as these can damage bits and degrade cut quality.

Routinely inspect bits for wear and chips; dull or damaged bits should be replaced promptly.

Clean bits after use to remove pitch and resin build-up.

Store bits carefully to prevent damage and maintain cutting edges.

Raised Panel and Mortising Router Bits are indispensable tools that empower woodworkers and construction professionals to produce work that excels in both form and function. Raised Panel Bits elevate the visual appeal of cabinetry and furniture with elegant profiles, while Mortising Bits provide the strength and precision necessary for structural joinery.

For companies like YUEQING LAIWEI TOOLS CO., LTD, which specialize in high-quality router bits, these products represent the intersection of craftsmanship and technology. By incorporating these bits into their workflows, carpenters and builders can enhance productivity, reduce errors, and achieve consistently excellent results.

Whether on a busy construction site or a detailed woodworking shop, mastering the use of Raised Panel and Mortising Bits is key to delivering woodwork that is not only attractive but built to last. Investing in the right tools today ensures that tomorrow’s projects stand strong and look stunning for years to come.